When Should You Use Fine Or Course Threads

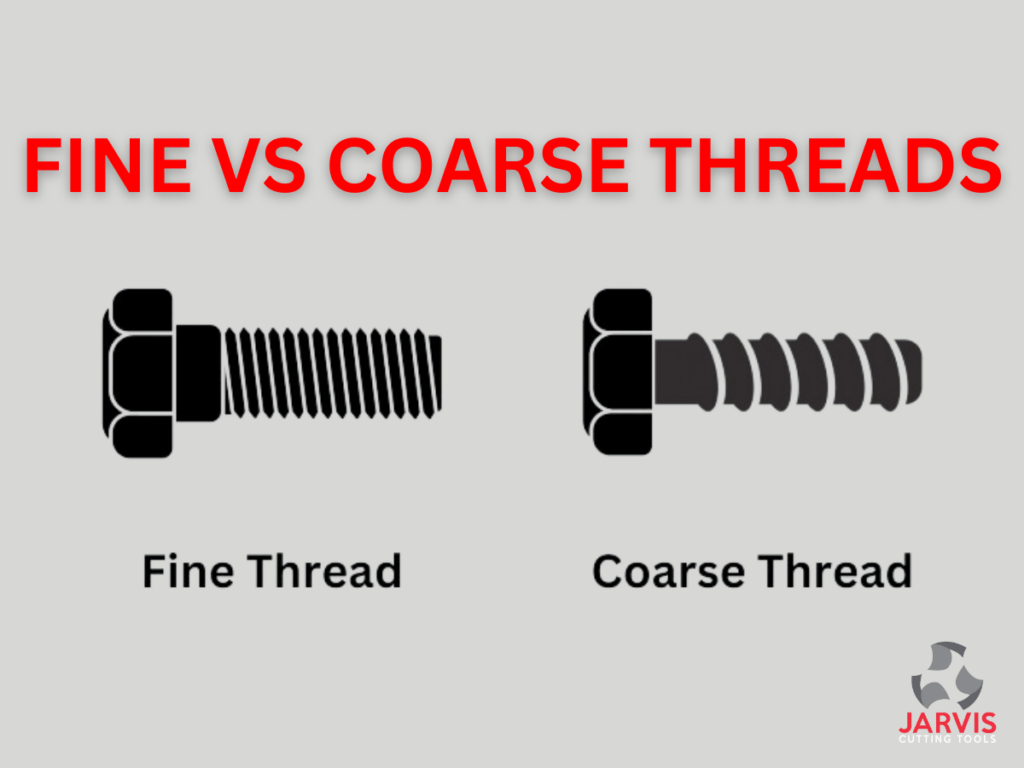

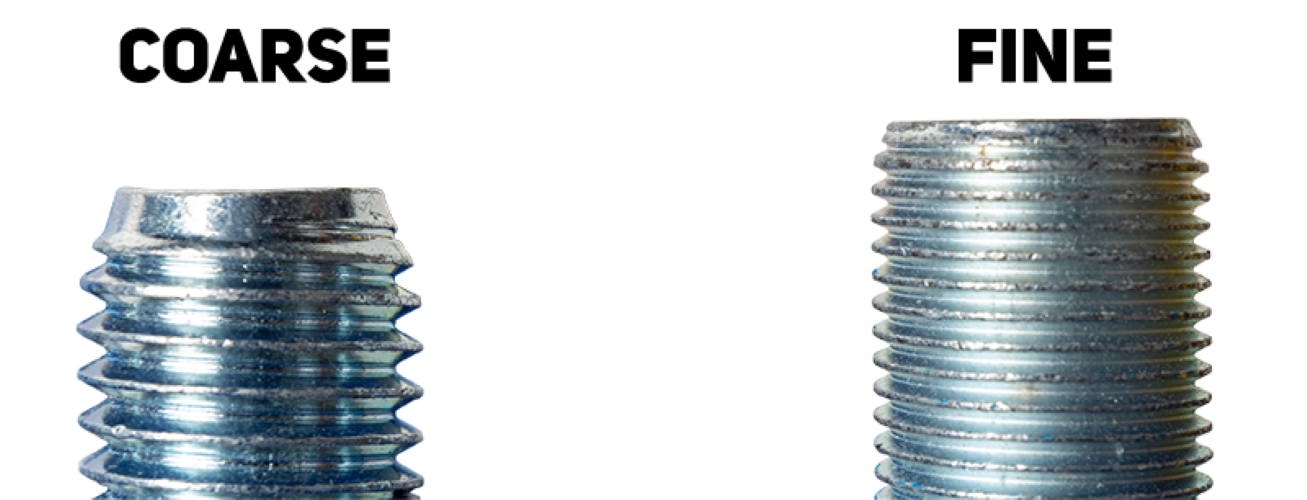

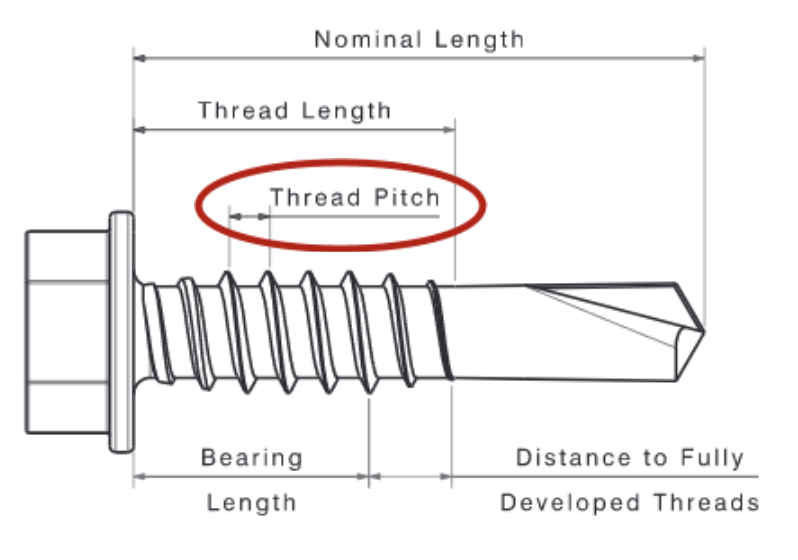

When Should You Use Fine Or Course Threads - Coarse threads are best suited for applications requiring. Fine threads provide finer adjustment since they advance less per rotation than coarse threads. This will depend on the specific application. Fine threads have more threads per inch so this will give you more gripping area in a smaller length. However, fine threads are ideal for applications demanding specific strength. Whether securing materials on a bustling construction site or crafting a delicate. Bolts with coarse threads have a larger pitch (fewer threads per axial distance) compared to fine threads. + fine threads are more susceptible to thread galling than coarse threads. Fine threads excel at gripping dense materials like wood. Fine threads are great for fine adjustment when compared to coarse threads. A coarse threaded bolt is specified for most applications unless there is an overriding. This will depend on the specific application. The metric coarse thread is actually between un coarse and fine thread, and the metric fine. Whether securing materials on a bustling construction site or crafting a delicate. The coarse threads are suited for most applications; + fine threads need longer thread engagements and are more prone to damage (nicking) and thread fouling. Some fasteners have coarse threads, whereas others have fine threads. They also have larger tensile stress areas which in turn make them stronger in tension than coarse threads. Fine threads provide finer adjustment since they advance less per rotation than coarse threads. Fine threads provide enhanced precision, greater thread engagement, and resistance to corrosion. + fine threads are more susceptible to thread galling than coarse threads. First let’s look at fine compared to coarse thread. Bolts with coarse threads have a larger pitch (fewer threads per axial distance) compared to fine threads. Fine threads are more susceptible to galling than coarse threads. Purchase two spools or wind a bobbin from a single spool to. This will depend on the specific application. First let’s look at fine compared to coarse thread. The coarse threads are suited for most applications; Whether securing materials on a bustling construction site or crafting a delicate. A coarse threaded bolt is specified for most applications unless there is an overriding. When should i use fine thread fasteners vs coarse thread fasteners? Some fasteners have coarse threads, whereas others have fine threads. A coarse threaded bolt is specified for most applications unless there is an overriding. First let’s look at fine compared to coarse thread. Whether securing materials on a bustling construction site or crafting a delicate. Coarse threads are best suited for applications requiring. Consider the following factors when deciding between coarse and fine thread wood screws: The choice between fine thread and coarse thread is determined by the application and materials used. They also have larger tensile stress areas which in turn make them stronger in tension than coarse threads. Purchase two spools or wind. So what differentiates these two types of threads?. Fine threads are great for fine adjustment when compared to coarse threads. Fine threads are more susceptible to galling than coarse threads. The choice between fine thread and coarse thread is determined by the application and materials used. Fine threads have more threads per inch so this will give you more gripping. Fine threads excel at gripping dense materials like wood. Fine threads have more threads per inch so this will give you more gripping area in a smaller length. Fine threads provide finer adjustment since they advance less per rotation than coarse threads. The metric coarse thread is actually between un coarse and fine thread, and the metric fine. The coarse. Some fasteners have coarse threads, whereas others have fine threads. Fine threads provide enhanced precision, greater thread engagement, and resistance to corrosion. When should i use fine thread fasteners vs coarse thread fasteners? Fine threads are more susceptible to galling than coarse threads. They need longer thread engagements and are more prone to damage and thread fouling. Purchase two spools or wind a bobbin from a single spool to. They need longer thread engagements and are more prone to damage and thread fouling. Consider the following factors when deciding between coarse and fine thread wood screws: + fine threads need longer thread engagements and are more prone to damage (nicking) and thread fouling. Fine threads are more. Purchase two spools or wind a bobbin from a single spool to. Consider the following factors when deciding between coarse and fine thread wood screws: This will depend on the specific application. They also have larger tensile stress areas which in turn make them stronger in tension than coarse threads. Fine threads provide enhanced precision, greater thread engagement, and resistance. Consider the following factors when deciding between coarse and fine thread wood screws: Fine threads provide enhanced precision, greater thread engagement, and resistance to corrosion. Coarse threads are best suited for applications requiring. This is because the amount a nut would travel for one revolution of the fastener is less when. They also have larger tensile stress areas which in. Fine threads have more threads per inch so this will give you more gripping area in a smaller length. Fine threads are great for fine adjustment when compared to coarse threads. Bolts with coarse threads have a larger pitch (fewer threads per axial distance) compared to fine threads. Some fasteners have coarse threads, whereas others have fine threads. They also have larger tensile stress areas which in turn make them stronger in tension than coarse threads. First let’s look at fine compared to coarse thread. Fine threads provide enhanced precision, greater thread engagement, and resistance to corrosion. Coarse threads are best suited for applications requiring. The coarse threads are suited for most applications; Fine threads excel at gripping dense materials like wood. Whether securing materials on a bustling construction site or crafting a delicate. They need longer thread engagements and are more prone to damage and thread fouling. However, fine threads are ideal for applications demanding specific strength. The metric coarse thread is actually between un coarse and fine thread, and the metric fine. Coarse threads shine in rugged environments, while fine threads excel in precision and strength applications. Consider the following factors when deciding between coarse and fine thread wood screws:Coarse Threads vs Fine Threads Jarvis Cutting Tools

Technicals Fastener Thread Charts Fixaball Ltd. Fixings and Fasteners UK

Coarse Thread vs. Fine Thread Fasteners Key Differences and Uses

Fine Thread or Coarse Thread Fastener Which is Better?

Coarse vs Fine Threads ARMPRO

Fine vs. Coarse Threaded Fasteners

Fine Thread vs Coarse Thread Stenght + Usage SFS USA

Which should you use coarse threads or fine threads? JSK Enterprises

Coarse Thread Vs. Fine Thread Fasteners All Points Fasteners

How To Choose Coarse Thread Or Fine Thread For BoltsKnowledges News

Purchase Two Spools Or Wind A Bobbin From A Single Spool To.

This Will Depend On The Specific Application.

Fine Threads Are More Susceptible To Galling Than Coarse Threads.

They Are Also Less Suitable.

Related Post: