Instrumentation Courses

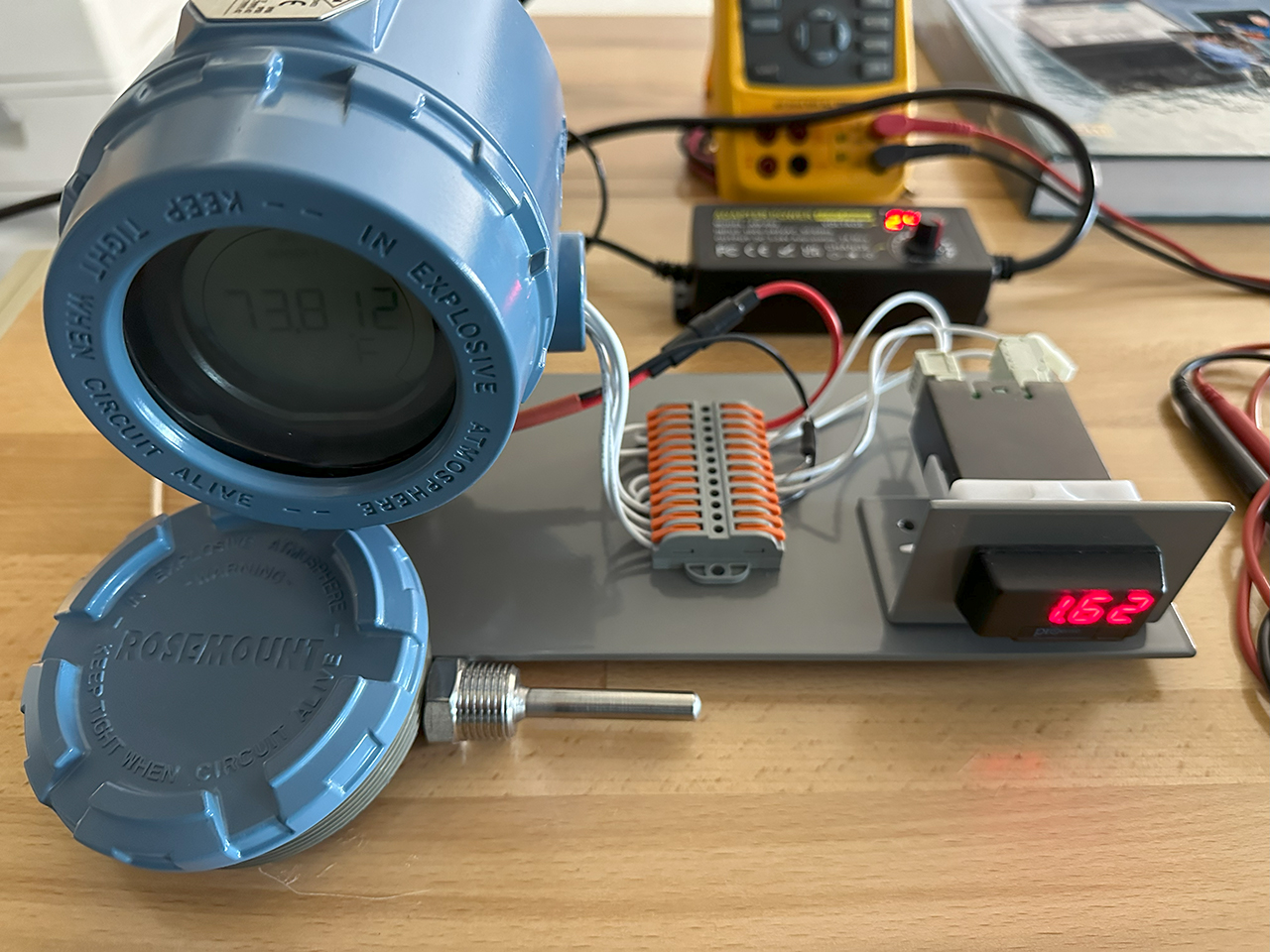

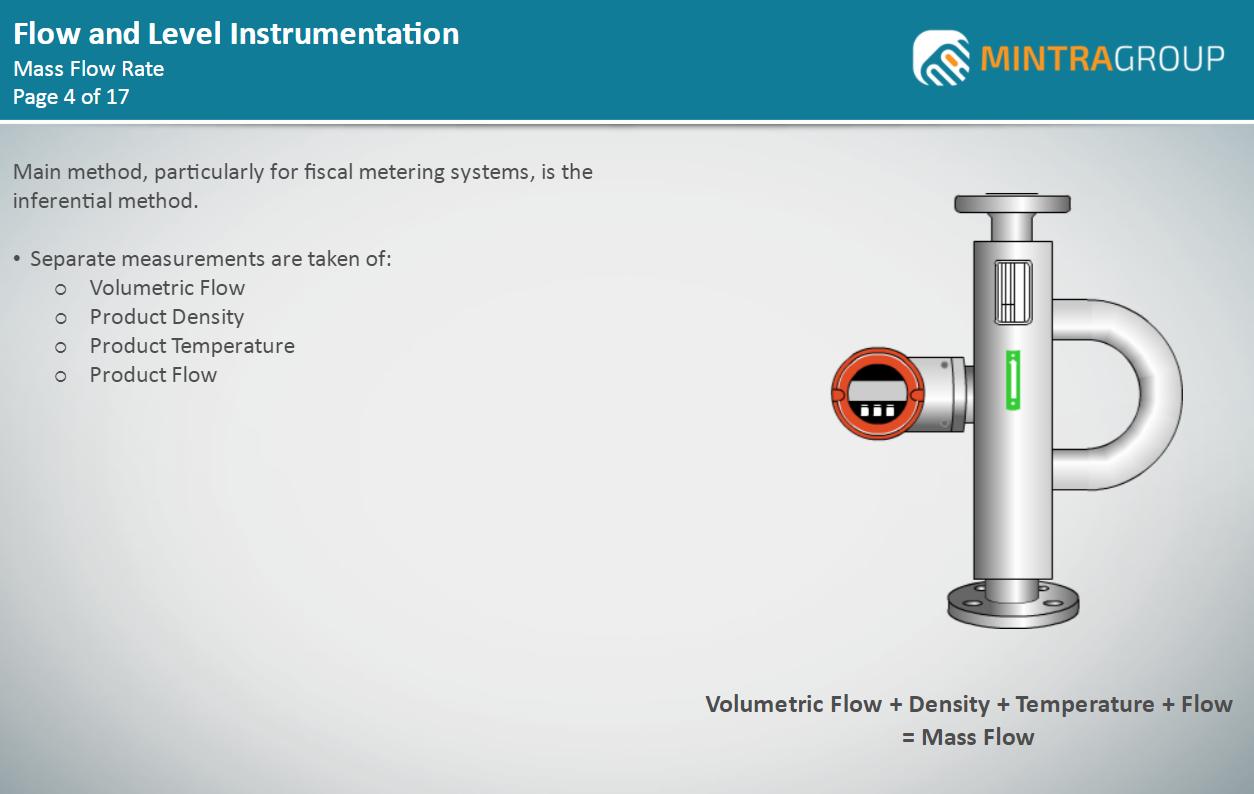

Instrumentation Courses - Whether you are new to instrumentation engineering, or a qualified engineer looking to upskill, we have the control and instrumentation training course for you. Changed mindset and government’s compliance put efforts to make safety as first priority against profits and production. Our online training provides technicians with knowledge of process variables, control systems, sensors, transmitters, control loops, and plcs needed to install, maintain, and improve equipment, systems, and machinery. There will be weekly laboratory assignments where students will have hands on experience with various sensors. Instrumentation training involves learning to work with and troubleshoot instrumentation systems. Our comprehensive instrumentation training course equips professionals with the technical expertise required to efficiently operate and maintain instrumentation systems, ensuring accurate measurements through proper instrumentation calibration, diagnostics, and maintenance. Listed below are some of the topics i will cover with you in this course. Comprehensive lessons on instrumentation fundamentals; Instrumentation & control technology, aas. The devices that you will work on are used in automated production. Comprehensive lessons on instrumentation fundamentals; As automation continues to grow, so does the demand for skilled professionals who can calibrate, maintain, and diagnose these systems across manufacturing, energy, and process control industries. Changed mindset and government’s compliance put efforts to make safety as first priority against profits and production. Industrial instrumentation is critical to modern industries, ensuring efficiency, accuracy, and safety in automated systems. The basic instrumentation course covers the fundamentals of instrumentation, process diagrams, loop drawings, dmm basics, and fundamentals of temperature, pressure, level, and flow. Provides review of technologies, terminology, and symbols needed to work in the field, understand p&ids and perform basic wiring techniques. This course introduces you to control in process industries, explains why control is important, identifies different ways in which precise control is ensured and illustrates the different set of instrumentation used to perform measuring tasks for temperature, pressure, flow and level. Fully animated course designed by industry experts Students will learn pressure for liquid level measurement and fundamentals of flow, including differential, electromagnetic, vortex, and coriolis flow measurement. Our online training provides technicians with knowledge of process variables, control systems, sensors, transmitters, control loops, and plcs needed to install, maintain, and improve equipment, systems, and machinery. The purpose of an instrumentation engineer is to conceptualize, design, detail, maintain and trouble shoot control system for its industry. Whether you are new to instrumentation engineering, or a qualified engineer looking to upskill, we have the control and instrumentation training course for you. Our comprehensive instrumentation training course equips professionals with the technical expertise required to efficiently operate and. The devices that you will work on are used in automated production. The purpose of an instrumentation engineer is to conceptualize, design, detail, maintain and trouble shoot control system for its industry. Instrumentation & control technology, aas. All our courses are industry accredited and taught by fully qualified consultants or engineers with practical and on. Fully animated course designed by. Check outr b.tech electronics and instrumentation engineering fees 2025, admission dates, eligibility, course duration, cutoff, placement, scholarship and more. This includes understanding process measurements, control systems, and various technologies like plcs, scada, and dcs. Whether you are new to instrumentation engineering, or a qualified engineer looking to upskill, we have the control and instrumentation training course for you. Instrumentation technology. Use various instruments to measure temperature, pressure, flow rate, level and position, ph, and analysis of weight and density. Our online training provides technicians with knowledge of process variables, control systems, sensors, transmitters, control loops, and plcs needed to install, maintain, and improve equipment, systems, and machinery. There will be weekly laboratory assignments where students will have hands on experience. Students will learn pressure for liquid level measurement and fundamentals of flow, including differential, electromagnetic, vortex, and coriolis flow measurement. Instrumentation & control technology, aas. Check outr b.tech electronics and instrumentation engineering fees 2025, admission dates, eligibility, course duration, cutoff, placement, scholarship and more. The purpose of an instrumentation engineer is to conceptualize, design, detail, maintain and trouble shoot control. Focuses on how energy systems work today and how they can work in a decarbonized sustainable future, while still meeting the critical energy needs of global developed and developing societies. The basic instrumentation course covers the fundamentals of instrumentation, process diagrams, loop drawings, dmm basics, and fundamentals of temperature, pressure, level, and flow. Listed below are some of the topics. Instrumentation training involves learning to work with and troubleshoot instrumentation systems. Fully animated course designed by industry experts As automation continues to grow, so does the demand for skilled professionals who can calibrate, maintain, and diagnose these systems across manufacturing, energy, and process control industries. Check outr b.tech electronics and instrumentation engineering fees 2025, admission dates, eligibility, course duration, cutoff,. This course is designed for beginners and will cover essential concepts and practical applications in the field. As automation continues to grow, so does the demand for skilled professionals who can calibrate, maintain, and diagnose these systems across manufacturing, energy, and process control industries. Industrial instrumentation is critical to modern industries, ensuring efficiency, accuracy, and safety in automated systems. Fully. • introduction to instrumentation for measurement and control. There are courses for all levels from begining technician to experienced plant manager. This includes understanding process measurements, control systems, and various technologies like plcs, scada, and dcs. Listed below are some of the topics i will cover with you in this course. Instrumentation & control technology, aas. This course is designed for beginners and will cover essential concepts and practical applications in the field. Focuses on how energy systems work today and how they can work in a decarbonized sustainable future, while still meeting the critical energy needs of global developed and developing societies. Comprehensive lessons on instrumentation fundamentals; Instrumentation & control technology, aas. Changed mindset and. Whether you are new to instrumentation engineering, or a qualified engineer looking to upskill, we have the control and instrumentation training course for you. These training courses include topics such as alarm management, scada systems, p&id loop, batch control, hmi, fire and gas systems, instruments, sensors and more. Our comprehensive instrumentation training course equips professionals with the technical expertise required to efficiently operate and maintain instrumentation systems, ensuring accurate measurements through proper instrumentation calibration, diagnostics, and maintenance. Instrumentation & control technology, aas. As automation continues to grow, so does the demand for skilled professionals who can calibrate, maintain, and diagnose these systems across manufacturing, energy, and process control industries. Listed below are some of the topics i will cover with you in this course. Provides review of technologies, terminology, and symbols needed to work in the field, understand p&ids and perform basic wiring techniques. This includes understanding process measurements, control systems, and various technologies like plcs, scada, and dcs. Instrumentation technology courses will teach you how to install, maintain, test, and calibrate highly complex devices that are used in the automation of industrial processes. The purpose of an instrumentation engineer is to conceptualize, design, detail, maintain and trouble shoot control system for its industry. The basic instrumentation course covers the fundamentals of instrumentation, process diagrams, loop drawings, dmm basics, and fundamentals of temperature, pressure, level, and flow. The devices that you will work on are used in automated production. • pid control including loop tuning. Use various instruments to measure temperature, pressure, flow rate, level and position, ph, and analysis of weight and density. There will be weekly laboratory assignments where students will have hands on experience with various sensors. Focuses on how energy systems work today and how they can work in a decarbonized sustainable future, while still meeting the critical energy needs of global developed and developing societies.️ field instrumentation training Inst Tools

Control and Instrumentation Training Courses — MCP Technical Training

Industrial Instrumentation Online Training Course

Handson Instrumentation & Controls Course

Introduction to Flow and Level Instrumentation Training Course

Instrumentation engineering beginner course [01] Introduction YouTube

Short Courses

Process Instrumentation SITRAIN Germany, Siemens Training

UEE40420 Cert IV in Electrical Instrumentation Meo Training

Instrumentation Engineering Course Overview, Specializations, and Careers

Students Will Learn Pressure For Liquid Level Measurement And Fundamentals Of Flow, Including Differential, Electromagnetic, Vortex, And Coriolis Flow Measurement.

All Our Courses Are Industry Accredited And Taught By Fully Qualified Consultants Or Engineers With Practical And On.

Tpc's Recommended Training Curriculum For Instrumentation & Control Systems Technician Includes 53 Technical Skills Courses.

Based On Academic Performance, Financial Need, And Specific Criteria, Like High Jee Ranks Or Cgpas Above 8.0.

Related Post:

![Instrumentation engineering beginner course [01] Introduction YouTube](https://i.ytimg.com/vi/R_XGAuxhmwA/maxresdefault.jpg)